The concept of "intelligent manufacturing equipment" has received widespread attention both inside and outside the manufacturing industry since it was first clearly stated as a development priority in the 2010 "State Council's Decision on Accelerating the Cultivation and Development of Strategic Emerging Industries". The "Twelfth Five-Year Plan for the Development of the Intelligent Manufacturing Equipment Industry" promulgated in 2012 clearly defines intelligent manufacturing equipment as "a general term for various types of manufacturing equipment with sensing, decision-making, and execution functions." As the key development direction of high-end equipment manufacturing and an important manifestation of the deep integration of informatization and industrialization, intelligent manufacturing equipment is the necessary material condition for the intelligentization of the manufacturing process and is also the core carrier of intelligent manufacturing. As industrialized countries around the world pay more and more attention to technological innovation, the development of intelligent manufacturing equipment has become the focus of global competition.

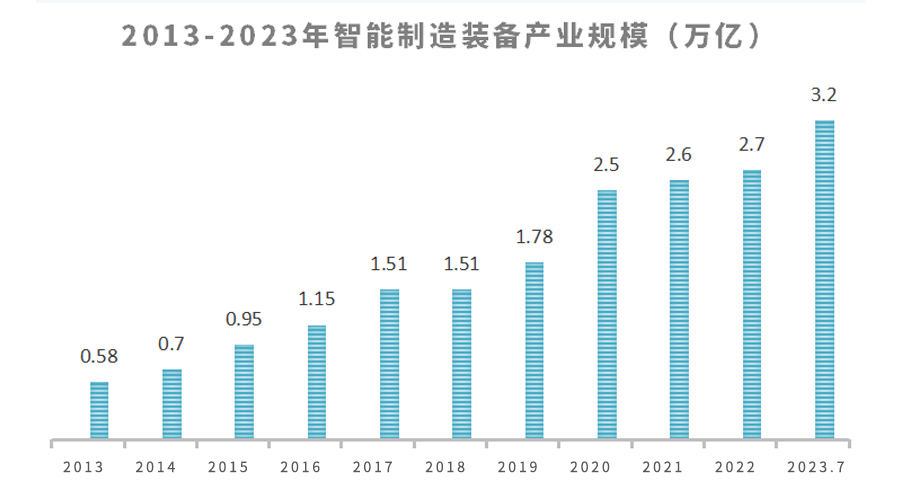

With the intelligent upgrading and transformation of the manufacturing industry, my country's intelligent manufacturing equipment industry has shown rapid growth. In 2022, there will be 83,900 new enterprises related to intelligent manufacturing equipment in my country. According to data from the Ministry of Industry and Information Technology, the current scale of my country's intelligent manufacturing equipment industry has exceeded 3.2 trillion yuan, and the market satisfaction rate exceeds 50%. More than 2,500 digital workshops and smart factories have been built, industrial software product revenue has exceeded 240 billion yuan, and there are more than 140 system solution providers with main business revenue of 1 billion yuan.

This article will briefly describe the current situation of the intelligent manufacturing equipment industry from three aspects: main industry policies, industry layout, and existing problems in the industry, and briefly analyze its future development trends.

The country attaches great importance to the intelligent manufacturing equipment industry and has introduced a series of policies to actively promote the development of the advanced equipment manufacturing industry.

Intelligent manufacturing is the main direction of "Made in China 2025" and an important measure to implement the strategy of manufacturing a strong country. It is the key for my country's manufacturing industry to keep up with the world's development trends and achieve transformation and upgrading. Among them, new generation information technology, high-end CNC machine tools and robots, aerospace equipment, marine engineering equipment and high-tech ships, advanced rail transit equipment, energy-saving and new energy vehicles, electric power equipment, new materials, biomedicine and high-performance medical equipment are proposed. , ten major fields of intelligent manufacturing of agricultural machinery and equipment, etc. It provides strong support and a good environment for the research, design and production of intelligent manufacturing equipment.

With the rapid development of information technology and advanced manufacturing technology, the depth and breadth of the development of my country's intelligent manufacturing equipment is increasing day by day. An intelligent manufacturing equipment industry system represented by new sensors, intelligent control systems, industrial robots, and automated complete production lines has initially taken shape. A batch of major intelligent manufacturing equipment with independent intellectual property rights have achieved breakthroughs, but key issues that restrict the development of intelligent manufacturing, such as interconnection of manufacturing links, remain unresolved. There is an increasingly urgent need for cross-industry and cross-field intelligent manufacturing standardization.

In order to guide the standardization work of intelligent manufacturing at present and in the future, the Ministry of Industry and Information Technology and the National Standardization Administration jointly issued the "Guidelines for the Construction of National Intelligent Manufacturing Standard System" in accordance with the strategic deployment of "Made in China 2025", which clarified the construction of intelligent manufacturing The overall requirements, construction ideas, construction content and organizational implementation methods of the manufacturing standard system have established an intelligent manufacturing standard system reference model from the three dimensions of life cycle, system level and intelligent functions, and thus proposed an intelligent manufacturing standard system framework. Including five basic common standards of "Basics", "Safety", "Management", "Detection and Evaluation", and "Reliability" as well as "Smart Equipment", "Smart Factory", "Smart Service", "Industrial Software and Big Data" , "Industrial Internet" five key technical standards and application standards for different industries including the 10 major application fields in "Made in China 2025".

On December 28, 2021, eight departments including the Ministry of Industry and Information Technology jointly issued the "14th Five-Year Plan for Intelligent Manufacturing Development", proposing that by 2025, supply capacity will be significantly enhanced, and the technical level of intelligent manufacturing equipment and industrial software will be Market competitiveness has been significantly improved, with market satisfaction rates exceeding 70% and 50% respectively, and more than 150 intelligent manufacturing system solution providers with high professional levels and strong service capabilities have been cultivated. On January 13, 2022, the Ministry of Industry and Information Technology, the Ministry of Science and Technology, and the Ministry of Ecology and Environment jointly issued the "Notice on Issuing the High-Quality Development Action Plan for the Environmental Protection Equipment Manufacturing Industry (2022-2025)", which proposed: By 2025, the technology of the environmental protection equipment manufacturing industry The level has been significantly improved, a number of key shortcomings in technical equipment that restrict the development of the industry have been achieved, and the supply capacity of high-efficiency, low-carbon and environmentally friendly technology and equipment products has been significantly improved, fully meeting major environmental governance needs. The comprehensive strength of the industry continues to increase, the core competitiveness steadily improves, a number of specialized and new "little giant" enterprises are created, and a number of individual manufacturing champion enterprises in subdivided fields with international competitive advantages are cultivated. The output value of the environmental protection equipment manufacturing industry strives to reach 1.3 trillion yuan. On February 21, 2023, seven ministries and commissions including the Ministry of Industry and Information Technology issued the "Action Plan for the Development of the Intelligent Inspection Equipment Industry (2023-2025)", which proposed that by 2025, intelligent inspection technology will basically meet the needs of manufacturing processes in the user field, with core components and special software And the supply capacity of complete machine equipment has been significantly improved. The demonstration and large-scale application of intelligent testing equipment in key areas have achieved remarkable results. The industry ecology has initially taken shape, basically meeting the development needs of intelligent manufacturing.

Judging from the regional competition pattern of the intelligent equipment industry, currently, my country's intelligent manufacturing equipment is mainly distributed in areas with a relatively developed industrial base. my country is forming four major industry clusters: the Pearl River Delta, the Yangtze River Delta, the Bohai Rim and the central and western regions. Industry clusters will further enhance the development level of intelligent manufacturing in various regions.

Among them, the Bohai Rim region and the Yangtze River Delta region are the core areas for equipment manufacturing. The R&D and production enterprises in the intelligent manufacturing equipment industry with CNC machine tools as the core are mainly distributed in the Bohai Rim region, the Yangtze River Delta region and the northwest region, with the highest concentrations in Liaoning, Shandong, Beijing, Shanghai, Jiangsu, Zhejiang and Shaanxi. In addition, key basic components and general components, and intelligent special equipment industries are also showing rapid development trends in Henan, Hubei, Guangdong and other regions, among which Luoyang, Xiangfan, and Shenzhen are the most prominent. At the same time, industrial robots will be a new hot spot in the development of intelligent equipment in the future, and Beijing, Shanghai, Guangdong, and Jiangsu will be the main markets for domestic industrial robot applications.

Bohai Rim Region: Relying on the advantages of regional resources and human resources, an industry pattern of staggered development of "core area" and "two wings" has been formed. Among them, Beijing has outstanding advantages in software fields such as industrial Internet and intelligent manufacturing services.

Yangtze River Delta region: Cultivate a number of intelligent manufacturing equipment industry clusters with outstanding advantages and distinctive features, and the development level of intelligent manufacturing is relatively balanced.

The Pearl River Delta region: Accelerate the replacement of machines and gradually develop into the main position of "Made in China". Among them, Guangzhou focuses on the construction of the core area of the robot and intelligent equipment industry, and Shenzhen focuses on building a manufacturing base, an international cooperation base and an innovative service base for the robot and wearable device industries.

The central and western regions: lag behind the eastern regions and are still in the automation stage. Relying on the advantages of universities and scientific research institutes, and taking the advanced laser industry as the "new highlight" in the development of intelligent manufacturing, an advanced laser industry with leading technology and outstanding features has been developed.

The intelligent manufacturing equipment industry is currently a key area of global manufacturing development, and its development plays an important role in improving the competitiveness and production efficiency of the manufacturing industry. Internationally, the intelligent manufacturing equipment industry is developing very rapidly, mainly in Europe, America and Asia. Among them, countries such as Germany, the United States, and Japan are in a leading position in the intelligent processing equipment industry.

Germany's intelligent manufacturing equipment industry has a long history of development and leading technological level. With the proposal and promotion of Industry 4.0 in Germany, the development of the intelligent manufacturing equipment industry has been further promoted. Regardless of advanced technology or high-quality products and services, it has a strong competitive advantage in market competition.

The smart manufacturing equipment industry in the United States is also a rapidly developing field. In recent years, due to increased government support and capital investment, the intelligent processing equipment industry in the United States has gradually grown and is actively exploring innovation in areas such as intelligent manufacturing and the Internet of Things, especially in technologies such as 3D printing, artificial intelligence, and machine learning. Research has made important progress.

In Asia, Japan's smart manufacturing equipment industry is also one of the leading industries. It has advantages in robotic applications, automated control, and high speed.

In recent years, China's intelligent manufacturing equipment industry has also begun to develop rapidly, and has achieved important results in the fields of robots, intelligent manufacturing, and automation products. China's intelligent manufacturing equipment manufacturers are also constantly improving their product innovation capabilities, technology levels and service levels, and the pace of internationalization is accelerating.

The foundation of my country's intelligent manufacturing equipment industry is weak, and the overall strength of supporting companies in the industry is weak. Some advantageous companies have made breakthroughs in the overall technology and integration capabilities of the system, but the manufacturing of some core components still lacks supporting support and their development is restricted. There is a big gap between the upstream and downstream core components and core technologies of smart equipment and the international advanced level. The independent supporting supply rate is low and the dependence on products is high.

Most of the core components of smart equipment, such as industrial chips, sensors, high-performance servo motors and drives, programmable controllers (PLC), and precision reducers for robots, still rely on imports. At the same time, machine tools, known as the mother of industry, are one of the indispensable equipment for the intelligent equipment manufacturing industry. However, most high-end precision machine tools and cutting tools are monopolized by foreign companies, resulting in high introduction costs and high subsequent use and maintenance costs. There are relatively few technological innovations and exchanges between industries in the region, and there is no positive interactive support between industries. As a result, my country's intelligent manufacturing equipment industry has a weak ability to resist risks. Once the international situation changes, it will be greatly affected.

The intelligent manufacturing equipment industry started late in my country, and its product technology has long lagged behind industrially developed countries. The market is mainly dominated by well-known international manufacturers, and most of the market share is also occupied by international brands. The industry's development is still highly dependent on foreign countries.

In recent years, with the strong support of the national strategy for the development of this industry, a number of outstanding intelligent equipment manufacturers have emerged in China. With their strong learning ability and technology research and development capabilities, they have integrated innovation, introduction, digestion, absorption, re-innovation and even originality. Through innovation and other methods, we have achieved technological breakthroughs and captured part of the market share.

However, the accumulation of enterprise technology R&D strength, the introduction or training of design and R&D personnel, and the promotion of strategically beneficial R&D projects all require a lot of time and financial support. Therefore, the number of domestic advantageous enterprises is still small and the industry organizational structure is small. , low brand awareness, weak competitiveness, and relatively weak risk resistance. The technological accumulation and market development of domestic products still need to go through necessary processes. The establishment of domestic brands also needs to go through the process of being gradually recognized by customers. It is still difficult to change smart manufacturing in the short term. The equipment market is dominated by well-known foreign manufacturers.

To sum up, the intelligent manufacturing equipment industry is the focus of international competition. Although there is still a certain gap between my country's intelligent equipment manufacturing industry and developed countries, under the good operating and development environment created by national and local government policies, my country's intelligent equipment manufacturing industry Four major industry clusters with different focuses have been initially formed, and the industry ecology has been initially formed, creating a good atmosphere for further improving the development level of intelligent manufacturing in various places.

The future development trend of my country's intelligent manufacturing equipment industry may be reflected in the following aspects:

With the joint efforts of the government, enterprises and all aspects of society, the formation and continuous development of the four major industry clusters, some domestic companies have made important breakthroughs in the field of intelligent manufacturing equipment. In key components such as industrial robots and machine vision, and intelligent special equipment, etc., it has successfully launched a series of intelligent manufacturing equipment with independent intellectual property rights, and its performance and quality have reached the international advanced level. In addition, with the transformation and upgrading of the domestic manufacturing industry, the demand for high-quality, high-performance intelligent manufacturing equipment is also increasing, which provides broad market opportunities for localized substitution and further promotes the process of localized substitution. Promote the transformation and upgrading of my country's manufacturing industry.

Although the self-sufficiency rate of domestically produced equipment has been increasing, generally speaking, it still faces a situation where core technology reserves are weak, products are mainly concentrated in mid- to low-end fields, and the level of localization of high-end equipment still needs to be improved.

The high-end equipment field is a strategic emerging industry led by high and new technologies and located at the high end of the value chain and the core link of the industrial chain. It determines the comprehensive competitiveness of the entire industrial chain and is the engine that promotes industrial transformation and upgrading. Vigorously cultivating and developing high-end equipment manufacturing industry is an inevitable requirement to enhance the core competitiveness of my country's industry. It is a strategic choice to seize the commanding heights of future economic and technological development. It is an important strategy for accelerating the transformation of economic development mode and realizing the transformation from a large manufacturing country to a powerful country. significance. In order to encourage the development of the high-end equipment field, in the "Decision of the State Council on Accelerating the Cultivation and Development of Strategic Emerging Industries", the high-end equipment manufacturing industry was listed as one of the seven strategic emerging industries to help the high-end equipment manufacturing industry develop rapidly and meet the requirements as soon as possible. Demand for localization in the field of high-end equipment.

Against this background, mastering core automation technologies and promoting the localization of high-end equipment have become the only way for my country's automation industry to enhance its comprehensive competitiveness and strive to become bigger and stronger. Therefore, under the circumstances of policy encouragement and urgent market demand, the competition among enterprises in the industry in the future will be reflected in the competition of technology accumulation, and technical strength will become a key element of future competition.

At present, through years of continuous investment, my country has made certain progress in the fields of optical imaging, mechanical systems, electrical control, artificial intelligence algorithms and information system software, promoting the localization process of my country's key components. As smart manufacturing technologies such as industrial robots and automated testing continue to gain popularity in key industries such as semiconductors and lithium batteries, the research and development and progress of semiconductor automation equipment and lithium battery automation equipment have become the focus of widespread attention, attracting a large amount of innovation resources. This will continue to promote the deepening of industrial automation and intelligence, and manufacturing process control and manufacturing execution systems will not spread and become popular throughout the industry, thereby further promoting the transformation and optimization of production technology in industries such as consumer electronics, new energy vehicles, energy storage, and photovoltaics. , further releasing production capacity in related industries.

In addition, the innovative development of the industrial Internet is also constantly focusing on smart manufacturing. Using scenarios as the entry point to continuously solve the difficulties and pain points of enterprises will become the key to breaking the situation of industrial digitalization.

Judging from the market demand trend, market demand tends to be diversified and personalized, and industrial automation has become an excellent choice for factories to improve production efficiency. The factory needs to manage these machines to maximize the efficiency of equipment resources. Automation is upgraded to a smart factory. A large amount of data is collected to the cloud server through the Internet of Things. These data and analysis models are then used to calculate the efficiency of the machine, predict the occurrence of failures, optimize the production process and improve the design plan; managers can control production in real time. Progress and reasonable scheduling; sales staff can conduct business negotiations based on the production line situation, ultimately maximizing overall efficiency, thereby making the overall operation of the factory easier to control, which is also the general trend.

Faced with the changing product demands of the market, factories need to achieve efficient and mass production of personalized products, which has generated a large number of customized demands for intelligent manufacturing equipment.

Different industries and different users in the same industry, according to their own business needs, have certain differences in the construction and use of the overall system in addition to the commonality of basic principles and general equipment, in its specific use and functions. In order to enable the systems built by customers to be closer to the needs of use, each intelligent manufacturing equipment company needs to make plans based on the customer's industry characteristics, industry specifications, product types, functional requirements, related supporting projects, customer budget and many other factors in the early stages of project construction. Design, and carry out customized software and hardware product development and implementation plan design according to customer needs, in order to better serve customers and build an intelligent application system that truly meets customer needs and is highly efficient.

Therefore, the future development of the intelligent manufacturing equipment industry will also focus more on product customization. The company will customize and develop intelligent manufacturing equipment based on customer needs and provide related supporting technical services. Therefore, rich implementation experience and customized R&D, design, manufacturing, and implementation capabilities are the objective needs and long-term development trend of the industry.

With the continuous improvement of global environmental awareness, the development of the intelligent manufacturing equipment industry has also paid more attention to green environmental protection. More and more companies and their supply chains are beginning to adopt more environmentally friendly technologies and equipment to reduce environmental pollution in the production process and achieve sustainable development.

Take Apple as an example. Apple has been advocating green environmental protection for many years, and its entire supply chain system has also begun to use clean energy, more environmentally friendly equipment, etc. in its operations to reduce its impact on the environment.

Its equipment supplier Bozhon Seiko, in the process of cooperation with Apple, achieves green production by using photovoltaic power generation and purchasing green electricity in daily production and operations. It also develops, designs, and manufactures more green and environmentally friendly products for it. Manufacturing Equipment.

For example, at the first Chain Expo, Bozhon Seiko demonstrated a "high-definition UV inkjet printer" specially developed for Apple. The device supports ultra-small font printing and can achieve high-speed and high-resolution printing without the need for paper labels. Print directly on the iPhone box. It is estimated that removing these labels will avoid the use of more than 300 tons of plastic and more than 150 tons of paper, and reduce more than 3,700 tons of carbon emissions.

In general, China's intelligent manufacturing equipment manufacturing industry is still in a stage of rapid development. Enterprises in the industry are constantly strengthening their ability to improve product innovation, technology and service levels. The intelligent equipment manufacturing industry has reached considerable scale, with robots, intelligent manufacturing, There has been considerable growth in areas such as automation products.

The future development of the intelligent manufacturing equipment industry shows trends such as paying more attention to technological innovation and accelerating the localization process; customized production models are prevalent; intelligent production has become the core driving force and green environmental protection has become an important consideration. At the same time, as the global manufacturing industry continues to upgrade and transform, the intelligent manufacturing equipment industry will play a greater role in promoting economic development and improving social production efficiency.