Lithium batteries already play an important role in global economic development, and their market size is also growing rapidly. The "Global Lithium Battery Industry Supply and Demand White Paper" report shows that global lithium battery demand is expected to reach 680GWh in 2022, and the market size will reach 660 billion yuan; by 2025, lithium battery market demand will reach 1,778GWh, and the market size will exceed 1.400 billion yuan.

According to the ranking of global electric vehicle power battery installed capacity in October 2022 released by South Korea's market research institution SNE Research. The global production capacity of power lithium batteries is mainly concentrated in China, Japan and South Korea in Asia. The top ten power lithium battery companies in the world are also occupied by these three countries, accounting for 92% of the production capacity. Today, we will take stock of the top ten power lithium battery companies in the world, each with their own unique features or newly released products.

Founded in 2011, CATL has ranked first among power battery companies in the world for six consecutive years. Its customers include Tesla, Volkswagen, BMW, Mercedes-Benz, Toyota and other well-known large car companies.

On June 23, 2022, CATL released Kirin battery (third-generation CTP technology). Kirin Battery adds a water cooling plate in the middle of the two cells to reduce the heat conduction of the two adjacent cells and prevent thermal runaway. Secondly, it can meet high-voltage fast charging. 4C charging is not difficult and will be on the market next year. See; third, the battery life can be greatly improved because the water-cooled plate has a buffering effect; fourth, the specific energy is increased, and the Kirin battery can increase the utilization space. The energy density of the lithium iron phosphate system is 160wh/kg, and the ternary high nickel can reach 250wh/kg, which holds 30% more power than the 4680 battery.

This battery breaks through the functional boundaries, creating a three-in-one multi-functional elastic interlayer, and an original cell inversion scheme, which enables the battery pack volume utilization rate to exceed 72%. The energy density of Kirin battery system reaches 255Wh/kg. Under the same chemical system and the same battery pack size, its power capacity can be increased by 13% compared to the 4680 system. At the same time, CATL pioneered the large-area cooling technology for battery cells, which quadruples the heat exchange area of Kirin batteries, shortens the temperature control time by half, supports 5-minute hot start and 10-minute fast charging, and can achieve thermal stability and thermal stability of the entire chemical system. Safety improvements.

Kirin battery was also named the best invention of 2022 by Time magazine.

BYD was founded in 1995 and grew into the world's second largest rechargeable battery manufacturer in 2003. In terms of power batteries, BYD ranked second in the world from January to November 2022. Major customers include State Grid of China, CGNPC, Chevron of the United States, Fenecon of Germany, A-style of Japan, etc.

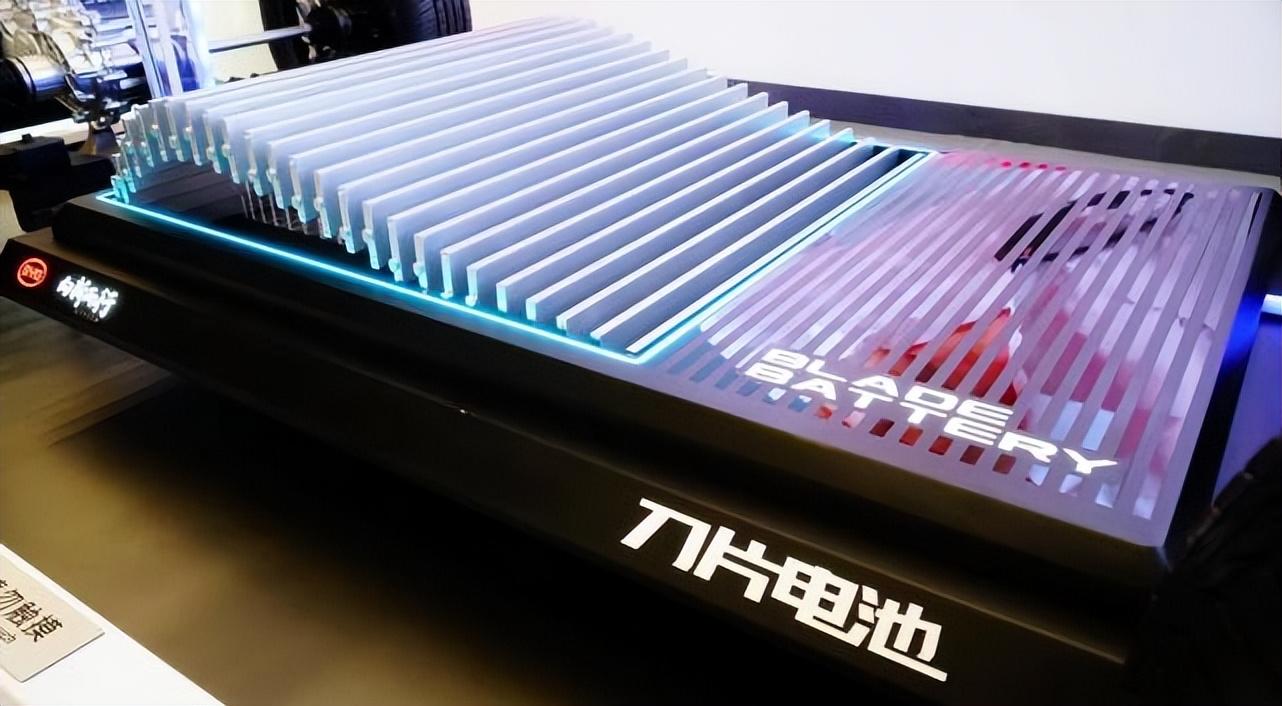

The Blade Battery is a battery product released by BYD on March 29, 2020. The battery uses lithium iron phosphate technology. However, the shape of the "blade battery" is completely different from the traditional lithium iron phosphate battery. The "blade battery" is a single battery cell that is "flattened" and grows long and thin, a bit like a blade, so it is called "blade battery" .

BYD's "Blade Battery" improves the space utilization in the battery pack by changing the structure of the battery pack. Its length, width and height are 960mm, 90mm, and 13.5mm respectively, and weighs about 2kg. This can greatly improve the reorganization efficiency of the battery cells. It also means that the energy density of the battery pack can be increased. Moreover, lithium iron phosphate batteries are not frost-resistant and have poor low-temperature performance, which is a well-known shortcoming in the industry. However, BYD's "blade battery" can still maintain a discharge capacity of 90% at minus 20 degrees Celsius. Not only that, it has low SOC at low temperatures. Under such circumstances, it performs better than ternary lithium.

"Blade battery" not only retains the advantages of traditional lithium iron phosphate batteries such as high safety, good high temperature resistance, long life, large charge and discharge rate, and low cost, but at the same time, its battery volume specific energy density is greatly improved, and its performance in low temperature environments It is also very stable. In this way, the advantages of lithium iron phosphate batteries in making up for the two major shortcomings of energy density and low temperature resistance are very obvious.

The blade battery also passed the "Mount Everest" in the field of battery safety testing - the acupuncture test, and successfully challenged the extreme strength test - the 46-ton heavy truck crush test. It has the characteristics of super safety, super strength, super endurance, and super lifespan. . Super safety: The battery is tested using seven safety dimensions, covering internal short circuit, external short circuit, overcharge, collision, high voltage, connection and dangerous gas; Super strength: the battery pack has the characteristics of no fire or explosion when squeezed, and has passed the simulated collision , compressive strength and other tests; super endurance: the cruising range easily exceeds 600km, super life: it can be charged and discharged more than 3,000 times, meeting the needs of the entire life cycle of the vehicle.

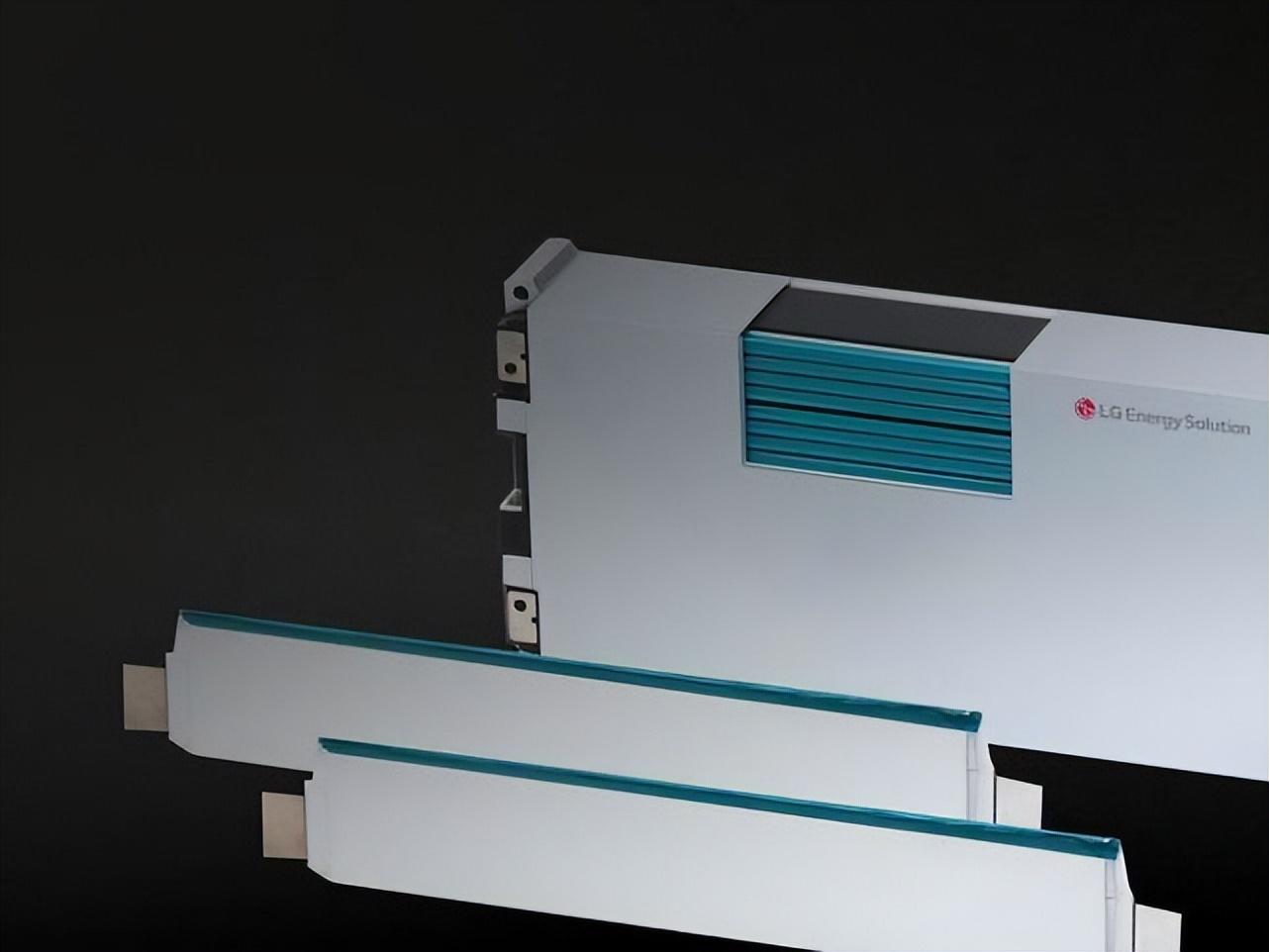

LG New Energy is affiliated to South Korea's LG Group and ranked third in the world in terms of installed capacity from January to November 2022. Provide power battery products for Volkswagen, General Motors, Daimler, Ford, Hyundai, Kia, Audi, Porsche, Renault, Tesla and other automobile brands.

As the world's first company to mass-produce ternary cathode materials, LG New Energy focuses on the market's demand for new energy vehicles with high cruising range and high safety, and is the first in the industry to achieve mass production of quaternary lithium batteries (NCMA) with upgrading nickel and reducing cobalt. Produce. High-nickel quaternary lithium batteries with aluminum added have the advantage of high energy density. Compared with ternary 8-series materials, they will significantly reduce the discharge heat flow peak and increase the peak temperature, so they have very excellent thermal stability. .

LG New Energy’s new generation quaternary battery technology can achieve a range of 650 kilometers on a single charge. At the same time, the highlight of this technical solution is that on the basis of high energy density of more than 300wh/kg, through advanced thermal management technology, super fast charging can be achieved. Charging can drive 280 kilometers in 5 minutes, which can fundamentally solve the current new energy problem. Range anxiety is common among users.

Panasonic is currently the only power lithium battery company in the top ten in Japan. It ranked fourth from January to November 2022. Its main customers are Tesla, Volkswagen, Toyota, Ford, etc.

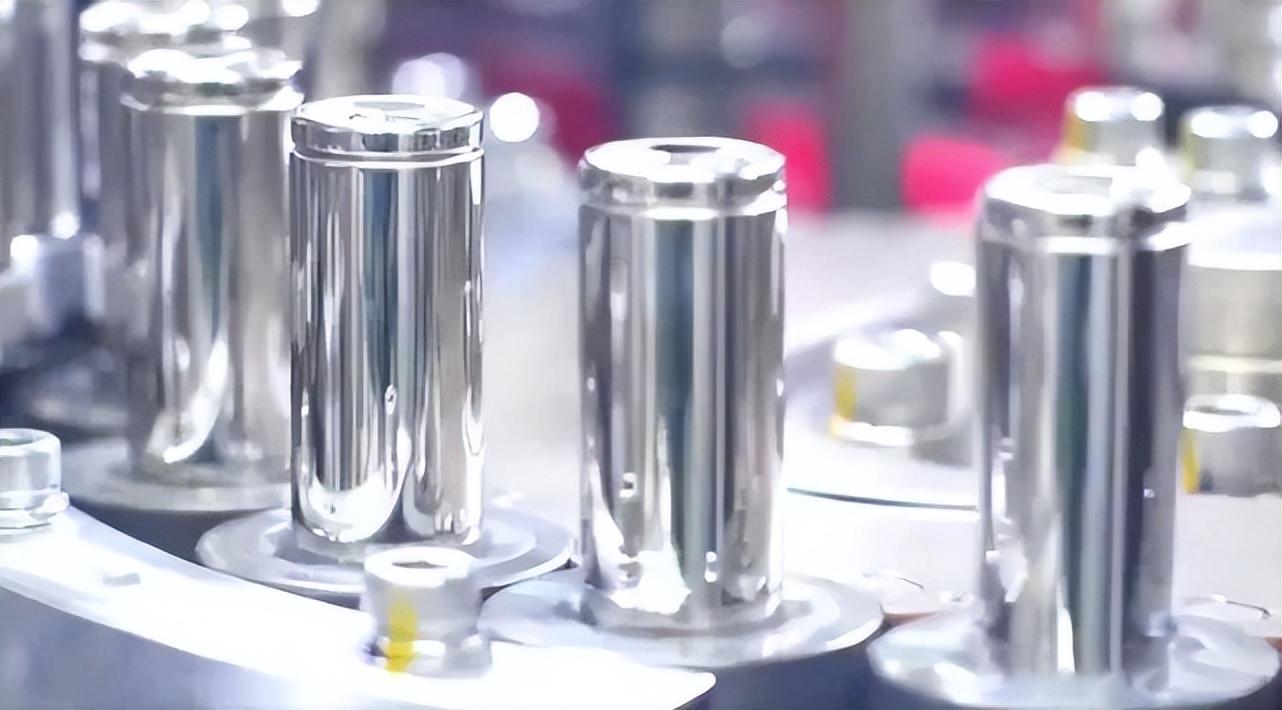

Panasonic's main power battery products are cylindrical batteries, and 4680 is its latest battery product. Different from the soft-packed or square battery cells used by traditional car brands, the cylindrical shape has gaps in the module or battery pack due to its shape, and the space efficiency is relatively poor. However, it also has many advantages, such as stability, fast heat dissipation, and low cost. Tesla's success is also due to the significant advantages of cylindrical batteries to some extent.

Compared with the previous generation 2170 battery, the battery volume of the 4680 battery is greatly increased, and the unit capacity is increased by 5 times. It also adopts a poleless ear design inside, which helps to reduce internal resistance and heat, thus bringing better energy consumption performance and better performance to the vehicle. Charging performance. In addition, Tesla also adopts a structured battery pack design, eliminating internal modules and directly consisting of batteries, which brings higher air utilization and improves the energy density of the entire battery pack. There will be approximately 960 cells in the battery pack, which is significantly reduced compared to the previous generation, thus reducing the burden on the battery management system.

Relying on the new 4680 battery and Tesla-controlled production technology, the cruising range of Tesla models will be increased by 54%, the battery cost per kilowatt hour will be reduced by 56%, and the investment cost per kilowatt hour will be reduced by 69%. In terms of parameters, the vehicle's cruising range will also be increased by 16%, which is 6 times higher than the electric power of the Julu battery.

SK On is a battery subsidiary spun off from the Korean company SK Innovation in early October 2021. It ranked fifth in the world from January to November 2022. Its main customers are well-known automobile manufacturers such as Hyundai, Kia, Mercedes-Benz, and BAIC.

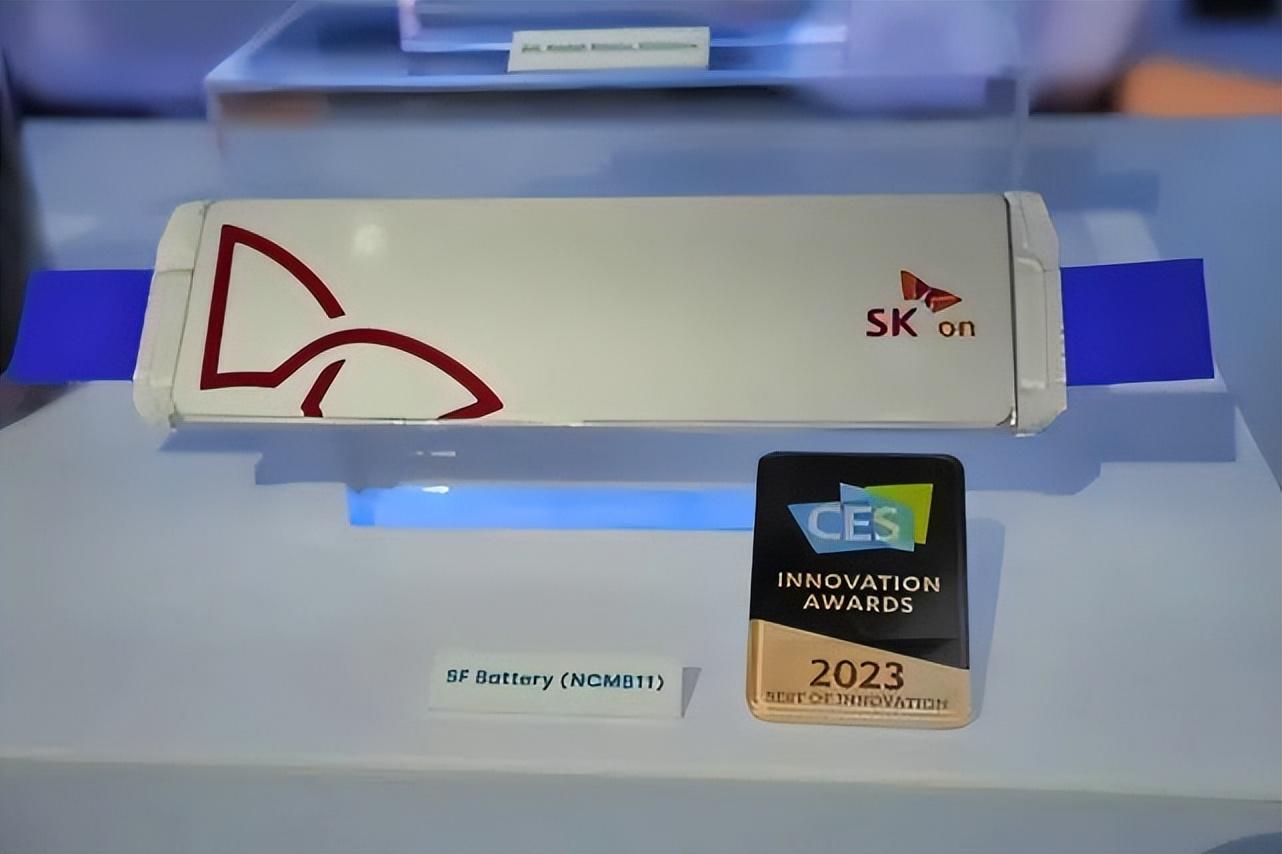

SK On, which has been one of the leaders in the global pouch battery industry, received a request from a global automaker in 2018 to build an electric vehicle (EV) that can be quickly charged in 18 minutes. Battery, the company agreed to the manufacturer's request and developed the SF battery (Super Fast Battery). SK On demonstrated this battery at this year's CES 2023 and obtained "embedded technology" Honorable Mention for Best Innovation in Category.

SK On applied its unique coating technology to significantly reduce resistance and proposed a new battery material that increases charging speed. The company also applied a manufacturing solution that minimized the use of SBR, an adhesive that causes cell resistance during the coating process.

For SF batteries, the battery life is not affected by fast charging, and the cycle life can reach 1,000 times. SK On said this is an achievement achieved after the company's rigorous testing.

SK On completed the development of SF batteries in 2019, and in 2021, electric models equipped with SF batteries debuted on the market. The company now aims to create batteries that can be quickly charged in 10 minutes.

Samsung SDI is a subsidiary of South Korea's Samsung Group. It ranked sixth in the world from January to November 2022. Its main customers include Tesla, Samsung, Ford, BMW, Volvo, Volkswagen, Audi, Jaguar, Fiat, etc.

The exterior of the Samsung SDI battery forms an ideal prismatic lithium battery casing in order to achieve minimal packaging space. In addition, no additional cooling module structure is required.

Samsung SDI's prismatic lithium-ion batteries can be designed to maintain stable internal air pressure on the outside of the prism, so there is no restriction on the selection of cathode, anode and electrolyte materials. Therefore, in order to achieve greater energy density, prismatic batteries can choose from a wider range of materials than any other form of battery.

Samsung SDI prismatic lithium-ion batteries have the highest level of built-in safety devices in the industry. Safety is the most important factor in battery production, because batteries rely on the reaction of some volatile chemicals to discharge, and some batteries have high energy density. Samsung SDI has developed and adopted its own unique safety equipment such as fuses, nail safety devices, overload safety devices and safety function layers to ensure driver safety under the harshest conditions.

Although a reduction in battery capacity is normal, the question is how to maintain high efficiency over the life of the battery. Samsung SDI's Lengdu batteries are sealed and assembled using laser splicing, so they are not affected by external temperature while maintaining sufficient electrolyte inside to ensure long-term stability of performance.

China New Aviation will become the world's seventh largest power battery manufacturer from January to November 2022. It was founded in 2015 and was formerly AVIC Lithium Battery with a background of state-owned enterprises. It will be listed on the Hong Kong stock market on October 6, 2022, and has established business relationships with car companies such as GAC, Xpeng, Changan, Leapmotor, Geely, Hechuang, Dongfeng, Honda, SAIC-GM-Wuling, Chery, Rich, Dongfeng Xiaokang and other car companies. .

Zhongxin Aviation has developed One-Stop's high manganese iron lithium battery, which has the following characteristics. One is better safety. It adopts TPP2.0 thermoelectric separation technology to ensure the robustness of system safety; secondly, it has better safety. , significantly reducing the amount of rare metals, including nickel, cobalt and lithium, helping everyone obtain lower purchase costs under the same conditions. The energy density of the battery pack has reached 180 watt-hours per kilogram, maintaining the energy density. The mileage rate exceeded 80%, supporting the vehicle to reach 700 kilometers. But these premise are still based on the premise that the height of the battery pack is about 110 mm. If it is made higher, it will have higher energy density and longer mileage. At the same time, in terms of user cost, China New Aviation has achieved less collisions, reduced height by 7%, and higher ground clearance. In terms of energy replenishment experience, it is rechargeable and replaceable. At the same time, the entire battery pack will be available on the market around 2024.

Guoxuan Hi-Tech was founded in 2006 and went public in May 2015. It will rank eighth in the world in 2022. Major customers include JAC, SAIC, GM, Wuling, Chery, BAIC and other large domestic automobile companies.

Mastering the semi-solid-state batteries of Guoxuan Hi-Tech, it already has a slight advantage on the road of solid-state batteries. The semi-solid battery is a new type of semi-solid flow battery developed by scientists from the Massachusetts Institute of Technology in the United States. It refers to a battery in which either side electrode does not contain liquid electrolyte and the other side electrode contains liquid electrolyte. Or the mass or volume of the solid electrolyte in the monomer accounts for half of the total mass or volume of the electrolyte in the monomer.

Compared with current lithium-ion batteries, semi-solid lithium batteries are smaller, more stable and safer. Simply put, the cost of semi-solid batteries is only one-third of the batteries used in existing electric vehicles, but the energy density is higher, which can double the driving range of electric vehicles on a single charge. Its flexible characteristics also make it safer.

It is understood that Gaohe Automobile HiPhi From the data point of view, it is already at the top level.

Sunwoda was founded in 1997. The company was listed in April 2011 and ranked ninth in the world in 2022. Sunwanda originally made lithium battery modules, strictly speaking, it was an OEM. The company's main customers are well-known domestic and foreign companies such as Apple, Philips, Amazon, Lenovo, OPPO, BBK, Haier, SanDisk, Topstar, Asus Linghaida, Ocean King, Mindray and other well-known enterprises.

The SFC480 super fast-charge battery is the first mass-produced super-chargeable battery independently developed by Sunwoda. It has breakthrough innovations in materials, processes, and structures. Sunwoda starts from two aspects: liquid cooling and battery cell technology. SFC480 uses a 3D liquid cooling technology that has higher heating and heat dissipation efficiency while taking into account low-temperature charging efficiency.

At the same time, the connection-less design of Sunwoda SFC480 battery cell is similar to that of a large cylindrical battery, eliminating the tab connection. The overall design can reduce the internal resistance of the battery cell by 3% and reduce the temperature rise by 2.5 degrees Celsius under the same overcharge current. The battery tab is the contact point between the positive and negative poles of the battery when charging and discharging. It is a metal conductor in the battery core that draws out the current from the positive and negative poles.

The SFC480 super fast-charging battery will be mass-produced this year, with a maximum charging power of 480 KW. It can achieve a cruising range of 700 kilometers on a single charge, and can support 200 kilometers of cruising after 5 minutes of charging. This means that Sunwanda is breaking through the shortcomings in technological innovation.

Everview Lithium Energy was founded in 2001 and was among the first to be listed on the Shenzhen GEM in 2009. In 2022, it ranked tenth in the world. Currently, Yiwei Lithium Energy's main customers include Xiaopeng, Dongfeng, GAC, GAC, Universiade, Hyundai Kia and leading domestic and foreign car companies such as Daimler, BMW, Jaguar Land Rover, and Bosch.

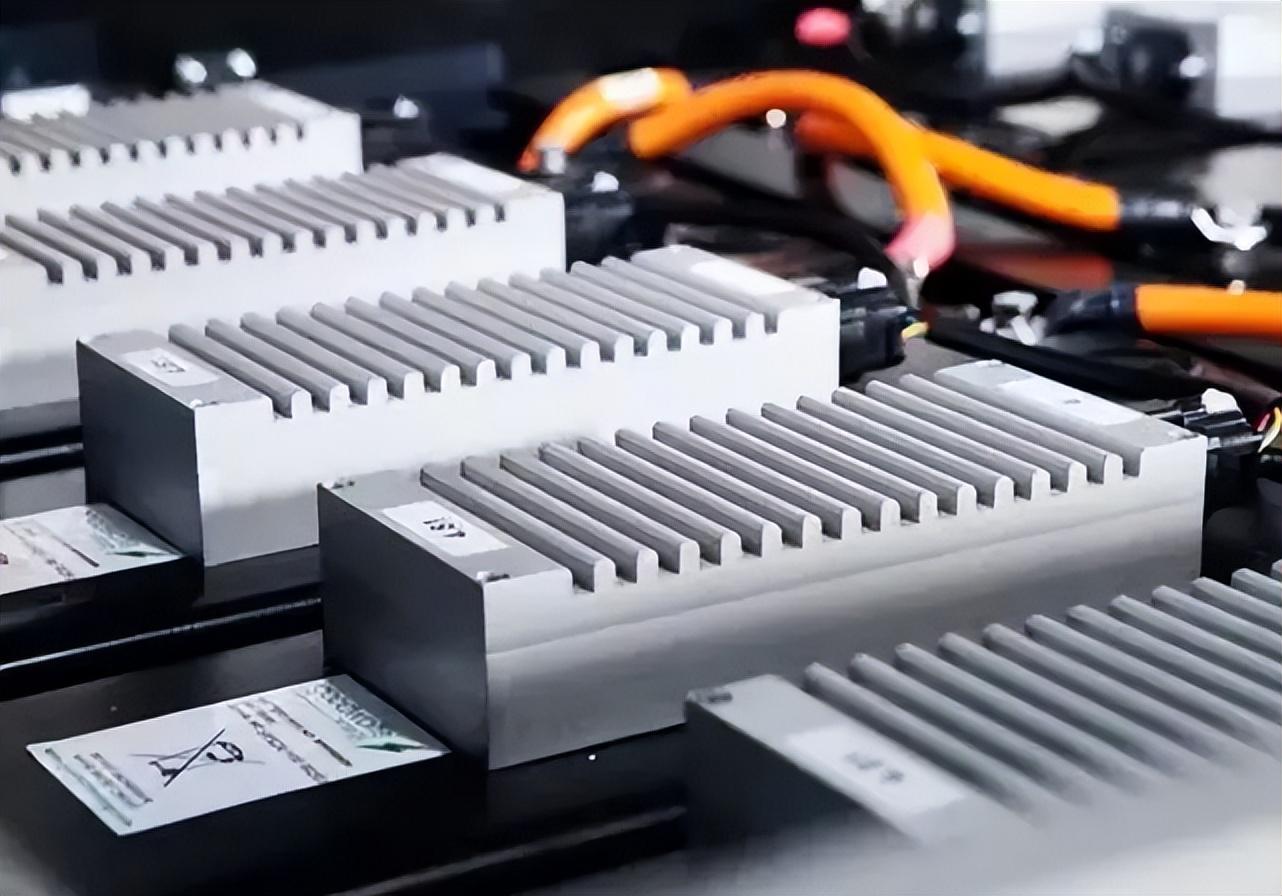

The 4695 large cylindrical battery has an energy density of 350Wh/kg and can achieve 9 minutes of ultra-fast charging and 500-1000km of battery life. Its production cycle is less than 7 days, manufacturing efficiency is increased by 30%, and manufacturing costs are reduced by 50%. At the same time, the company released a new cylindrical "π" battery system.

The company's fully automatic pilot line has produced a cumulative output of 500,000 batteries, with an overall excellence rate of 92%, overcoming technical difficulties such as flattening of all pole tabs, welding, and liquid injection. The first large cylindrical 20GWh factory is about to be built in Jingmen, Hubei Province, realizing the mass production of the first generation 280Wh/kg large cylindrical lithium battery products. The company plans to have a total large cylinder production capacity of over 100GWh in 2025, and will have production bases in Shenyang, Liaoning, Chengdu, Sichuan, Jingmen, Hubei, and Hungary.

The "π" battery system is a "π" cooling system developed by the company based on the 4695 large cylindrical battery. It has the characteristics of ultra-fast charging, high specific energy, long cruising range and high safety. Ultra-fast charging: three-dimensional heat transfer, the heat exchange area ratio is as high as 52.3m^2/Wh, which is 2.7 times higher than traditional cooling, and can achieve ultra-fast charging in 9 minutes; high specific energy: using new high-efficiency composite materials and high-strength lightweight new materials Adhesive, achieving 10% weight reduction of the system, and energy density reaching 260Wh/kg; high cruising range: ultra-high compatibility, can match the needs of different vehicle scenarios such as A/B/C-class cars or SUVs, and the cruising range can meet 500-1000 kilometers ; High safety: Establishing directional ultra-fast pressure relief and independent pressure relief channels can ensure the NTP of the system throughout its life cycle.

1. Safety. A series of safety incidents involving electric vehicle lithium batteries have deterred many new energy car owners from purchasing electric vehicles. How to ensure the safety of lithium batteries has become the primary consideration for lithium battery companies. In the products released by each company, they also mentioned what methods they have adopted to make batteries safer;

2. Energy replenishment. Compared with fuel vehicles, electric vehicles have always been at a disadvantage in terms of energy replenishment. Therefore, improving energy replenishment efficiency is a difficulty that all lithium battery companies must overcome. The cruising range that can be achieved within a certain charging time is another measure of the battery's fast charging capability. The U.S. Department of Energy (DOE) defines 6C charging as charging to 80% of the battery within 10 minutes, adding 322 kilometers of vehicle range. At present, all major lithium battery companies are constantly moving towards this indicator through technological innovation. Another way is to swap batteries. At present, CATL, BAIC, Aodong New Energy, NIO, Geely, FAW, SAIC, GAC and other companies have invested considerable manpower and material resources in developing battery charging and swapping station business. However, due to the high investment cost and narrow compatibility of charging and swapping stations, the speed of popularization is greatly limited. However, both at the government level and within the industry, there is an intention to formulate unified standards and lower the threshold for popularizing charging and swapping stations. Perhaps in the future, charging and swapping stations can be as common as gas stations today;

3. Battery mileage. Judging from the current data released by major lithium battery companies, electric vehicles have caught up with or even surpassed fuel vehicles in terms of cruising range, and there is still a lot of room for improvement in the future;

4. Reduce costs. Regardless of whether it is Yiwei Lithium 4695 large cylindrical battery, Guoxuan Hi-tech semi-solid battery, Zhongxin Aviation One-Stop's high manganese iron lithium battery, or Panasonic cylindrical battery, when they were released, they all mentioned the cost improvements of the products. optimization.

From these aspects, as various lithium battery companies continue to make breakthroughs in product technology, based on the needs of different application scenarios, multiple technical routes develop together and learn from each other and integrate, constantly promoting the optimization of battery performance and cost. The performance of new energy vehicles in all aspects continues to catch up or even surpass that of fuel vehicles, and is accepted by more and more intended car owners. The trend of new energy vehicles replacing fuel vehicles is becoming increasingly obvious. And judging from the current development trends of various companies, in the future, leading battery companies will build diversified technical routes to adapt to the application needs of different car companies and scenarios.

Finally, China has the world's largest new energy vehicle market, which is a huge advantage for Chinese lithium battery companies. This has also helped Chinese lithium battery companies occupy six of the top ten global power batteries, with a market share of more than 65%. In addition, relevant Chinese companies have controlled more than half of the world's lithium resources, a large part of which is in the South American Lithium Triangle, that is, Argentina, Chile, and Bolivia. These three countries have all joined the Belt and Road Initiative, and Chinese companies have invested here. There are huge political advantages in lithium mining and lithium mining. It is foreseeable that China will not be in a situation where there is no "lithium" available in the short term.

It can be said that in the field of lithium batteries, China has taken the leading advantage in all aspects of technology, market, and raw materials. Whether now or in the future, China will definitely have a huge say in the field of lithium batteries. But in the field of lithium batteries, the leader has changed hands several times, first to Japan, then to South Korea, and now to China. However, both Japan and South Korea are unwilling to give in and are always trying to catch up. In addition, Europe and the United States are also watching eagerly. China is far from the time to sit back and relax.