On May 18-19, 2020, the Suzhou Industrial Chain Global Cooperation Cloud Docking Event was held at the Suzhou International Expo Center. As a member of the intelligent equipment industry chain on Suzhou's Open Innovation Cooperation Heat Map, Bozhon, along with many other enterprises, ascended the "cloud" to boost global industrial chain innovation cooperation in Suzhou.

This event prominently introduced the fifth map of Suzhou's Open Innovation Cooperation Heat Map - the Industrial Chain Global Cooperation Docking Map. It will strengthen the supply and demand docking between Suzhou enterprises and global enterprises, helping businesses actively respond to the complex and severe international and domestic situations and the impact of the COVID-19 pandemic on the economy. By creating a unique, leading, and iconic industrial and innovation ecosystem in Suzhou, it aims to promote a new leap in the industrial chain system, build new industrial heights, and thereby lead the nation and the world.

The Suzhou Industrial Chain Global Cooperation Docking Map includes investment and business attraction information for five industrial chains: biopharmaceuticals and high-end medical devices, intelligent equipment, new display technologies, automobiles and parts, and software and integrated circuits. It also provides information on the distribution of these five industrial chains in Suzhou, as well as supply and demand information for upstream and downstream enterprises. As one of the 10,000 key enterprises in the industrial chain, Bozhon will use this as a basis to publish its own needs as well as information on products and services it can supply. It will seek docking and cooperation opportunities within the industrial chain to achieve precise demand matching.

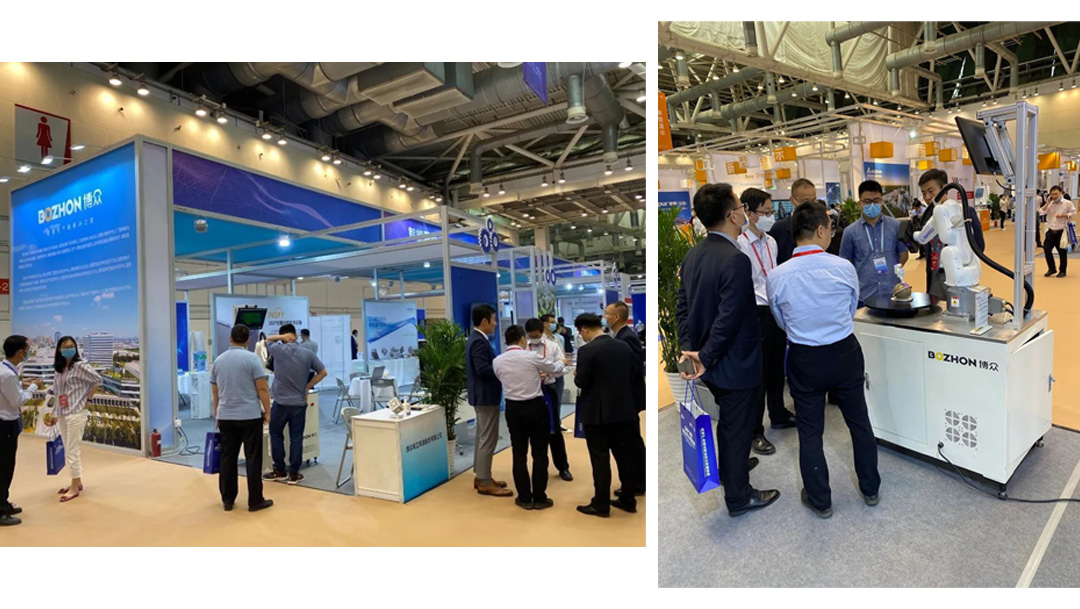

The offline matchmaking event also featured sub-forums and exhibition areas for the five industrial chains. Bozhon showcased products including a 360° cylindrical inner wall inspection device and a 3D camera.

The 360° Cylindrical Inner Wall Inspection Device, based on machine vision inspection technology, can detect appearance defects such as spots, dents, and micro-cracks on the inner surface of workpieces. Compared to similar products, this device can inspect highly reflective materials like metals, and the minimum detectable inner diameter can reach φ10mm, offering higher precision and faster speed.

The Rindo series 3D camera is suitable for inspection and measurement scenarios requiring micron-level precision, with a repeatability accuracy of up to 1um. It can be flexibly equipped with robotic arms and electric turntables, featuring intelligent path planning and automatic panoramic stitching. It meets the requirements of different resolutions and measurement ranges in the 3C measurement field.

The above equipment was developed by Bozhon Intelligent Equipment Business Center, which was established in early 2017. The center primarily provides customers with core vision components as well as system solutions for vision inspection and measurement. It is also a member of the China Machine Vision Union (CMVU) and the Japan Industrial Imaging Association (JIIA). With over 100 R&D personnel, 85% of whom have master's degrees or higher, the center possesses the capability for customized independent research and development, mainly serving major industries such as 3C, glass, OLED, LED, and new energy.

The robotic arms used in the equipment are provided by Linghou, a company that integrates R&D, production, sales, and service, focusing on core components in the field of intelligent manufacturing and industrial automation. The company has established R&D centers and bases in Suzhou, Shenzhen, Beijing, Silicon Valley in the United States, and Stuttgart in Germany, developing core automation components, key technologies, and algorithms. Its independently developed linear motor systems, machine vision systems, and industrial robot series products are widely used in industries such as automotive, medical, 3C, food, solar energy, semiconductors, new energy, packaging, and more.

In addition, Bozhon also provides customers with comprehensive digital factory solutions, created by the Bozhon Digital Factory Business Center. Based on the concept of the entire value chain of factory operations, focusing on the precision processing industry, it can provide enterprises with consulting, planning, and implementation services for building various elements of a digital factory, including manufacturing equipment automation, warehouse logistics automation, business process informatization, and lean production processes, helping enterprises achieve digital construction or digital upgrading of the entire value chain from product orders, R&D design, manufacturing to production delivery.

Regardless of how the external environment changes, Bozhon always deeply cultivates the intelligent equipment industry, continuously refining and strengthening its offerings. With the "hardcore artifact" of the Suzhou Open Innovation Cooperation Heat Map, Bozhon will continue to grasp the overall situation, take the initiative to seek industrial cooperation opportunities, strengthen the integration of the global industrial chain, promote industrial circulation, and help Suzhou in building, supplementing, strengthening, extending the chain, and accelerating the construction of a modern industrial system with international competitiveness!