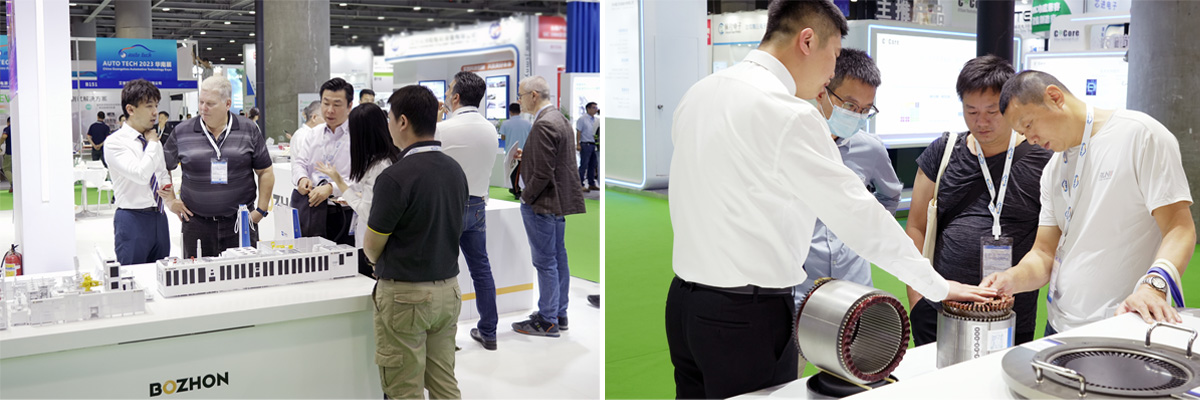

From November 1st to 3rd, "AUTO TECH 2023 China Guangzhou New Energy Vehicle Intelligent Manufacturing Expo" was successfully held in Hall 2 of Guangzhou Poly World Trade Expo Center. Bozhon Precision and Tecnomatic have been awarded invitations to participate in the event.

The primary focus of this exposition is to showcase the latest advancements in technology and equipment utilized in the production of new energy vehicle bodywork, batteries, electric drive systems, wiring harnesses, and other associated parts. A group of professional visitors, including representatives from the research and development, procurement, and other departments of original equipment manufacturers (OEMs) in the new energy vehicle industry, as well as first- and second-tier parts manufacturers, convened in Guangzhou to attend the exhibition.

At the exhibition, Bozhon Precision primarily displayed its recently developed production line for stators of new energy flat wire motors. The present product line exhibits stability and efficiency, enabling precise control. Additionally, it facilitates continuous operation by allowing the refueling of copper wire and insulating paper without the need to stop the machine. Moreover, it removes the slicing process, thereby mitigating potential quality hazards. The automatic production of new energy motor stators is achieved through modular design in various core equipment, including insulation paper insertion, pin forming automatic braided crown integral insertion, hole expansion and twisting, and laser welding. This design approach enables realizing an annual stator production capacity ranging from 100,000 to 300,000 units.

Bozhon Precision employed virtual reality (VR) technology for the inaugural time at the exhibition venue. The production line may be comprehended by audiences through the utilization of wire models and motor samples. Additionally, the incorporation of virtual reality (VR) technology enables a more intuitive understanding of the complete production process of flat wire motors.

Furthermore, Bozhon Precision was extended an invitation to participate in the "AUTO TECH 2023 New Energy Vehicle Drive Technology Forum" that was conducted simultaneously with the expo. Wang Siquan, a technical consultant and sales director of the Automotive Automation Division, assumed the role of a guest speaker and delivered a presentation centered around the topic of "Enhancing Productivity and Cost Efficiency through the Implementation of a Flat Wire Stator Flexible Automation Production Line." According to his statement, the limited number of Chinese enterprises that have successfully achieved mass production of flat wire motors can be attributed to challenges related to motor design, manufacturing processes, equipment, flat wire material, and energy loss. This presents a challenge in terms of enhancing the penetration rate, as it now falls short of meeting the increasing demand for new energy vehicles.

The establishment of a strategic relationship between Bozhon Precision and Tecnomatic will afford domestic motor firms the prospect of procuring product lines that offer excellent productivity and cost efficiency. These offerings will be available at reduced prices and with shorter delivery durations compared to imported alternatives. Simultaneously, these enterprises have the advantage of experiencing prompt responsiveness and comprehensive three-dimensional services, surpassing the capabilities of imported production lines. To a certain extent, the implementation of this solution is expected to address the existing challenges in the flat wire motor equipment market and contribute to the overall growth and advancement of the industry.

Currently, there is rapid growth in the new energy vehicle business, and there is a growing customer demand for these vehicles. The ongoing enhancement in power density and efficiency of drive motors poses a growing challenge for conventionally designed and manufactured motors to fulfill the competitive demands of the present market. Flat wire motors utilize flat rectangular wires, resulting in a substantial enhancement in power density when compared to conventional round wire motors. This advancement leads to a large reduction in overall copper consumption and an improvement in efficiency.

The advancement of technology has led to the widespread adoption of flat wire motors in new energy vehicles, replacing traditional domestic motors. Prominent manufacturers such as Tesla, BYD, and GAC have played a significant role in promoting the increased utilization of flat-wire motors in the new energy vehicle sector. Nevertheless, with the increasing adoption of flat-wire motors by numerous automotive firms, the industry's challenges have become increasingly apparent. Currently, the production of flat wire motors encounters challenges including the presence of numerous and intricate manufacturing procedures, as well as the dependence on foreign production lines and equipment that require substantial investments.

For numerous years, Bozhon Precision has actively engaged in the domains of new energy electric drive processes, automotive electronics processes, and automotive structural parts processes. The company's primary objective is to deliver top-tier integrated solutions for equipment assembly, testing, and transportation across the entire process to its esteemed clientele. The emerging field of new energy electric drive processes encompasses several components, including the stator, rotor, final assembly, automotive controller, and three-in-one electric drive assembly and testing production lines. The domain of automotive electronics manufacturing covers the assembly testing of Battery Management Systems (BMS), tire pressure sensors, and Programmable Logic Controllers (PLC). The field of automobile structural parts manufacturing comprises numerous parts such as EPS power steering systems, turbochargers, pump body assembly, exhaust catalyst delivery testing, and cooling tank assembly equipment, among others.

The establishment of a strategic alliance between Bozhon Precision and TM will enable them to collaborate and capitalize on their respective strengths to introduce a well-developed and reliable foreign flat wire motor production line design, research and development, and manufacturing capabilities. By using the comprehensive domestic supply chain system and relying on Bozhon Precision's integrated rapid delivery capabilities, the company aims to maximize its cost and delivery benefits to develop dependable and consistent equipment solutions for its clients. In the past, the company aimed to offer economically efficient products and services of superior quality to address the prevailing challenges within the flat wire motor equipment industry. This strategic decision will enhance the dynamism of the overall flat-wire motor equipment market and facilitate the collaborative establishment of a prominent Chinese brand in the field of flat-wire motor equipment.