Do you remember Takumi Fujiwara from "Initial D," who headed north? At the end of the movie, he wins against a GTR in the early morning with his tofu-laden AE86, as the sun slowly rises, surrounded by lush greenery on both sides of the road, leaning on the driver’s window with one hand, enjoying the cool breeze. And the tofu is still wobbling, just like the water in the cup.

So, why can they make the car drift instantly by turning the steering wheel in the movie?

Why does the car obediently turn in the direction we steer when we turn the steering wheel?

In fact, there’s a group of hard workers underneath the car, and that is the power steering system.

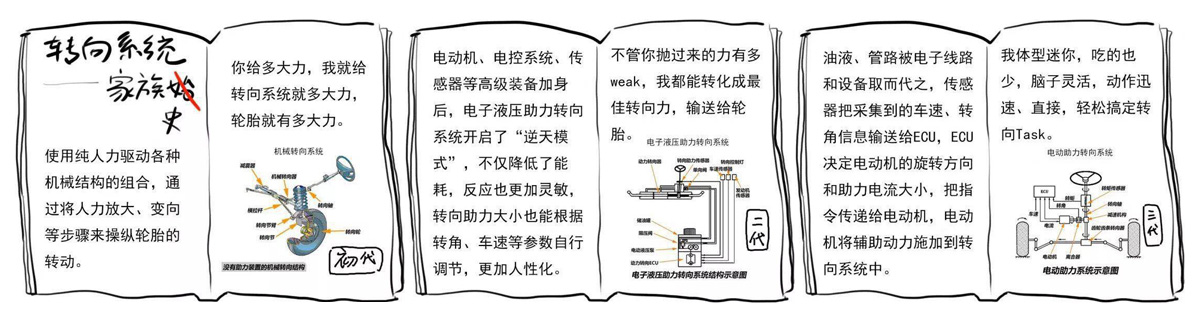

Before we delve into how the power steering system works so hard, let’s take a look at its family history~

First to appear is its great-great-grandfather…

OK, now that we’ve gone through its family history, let’s delve into how the power steering system works so hard~

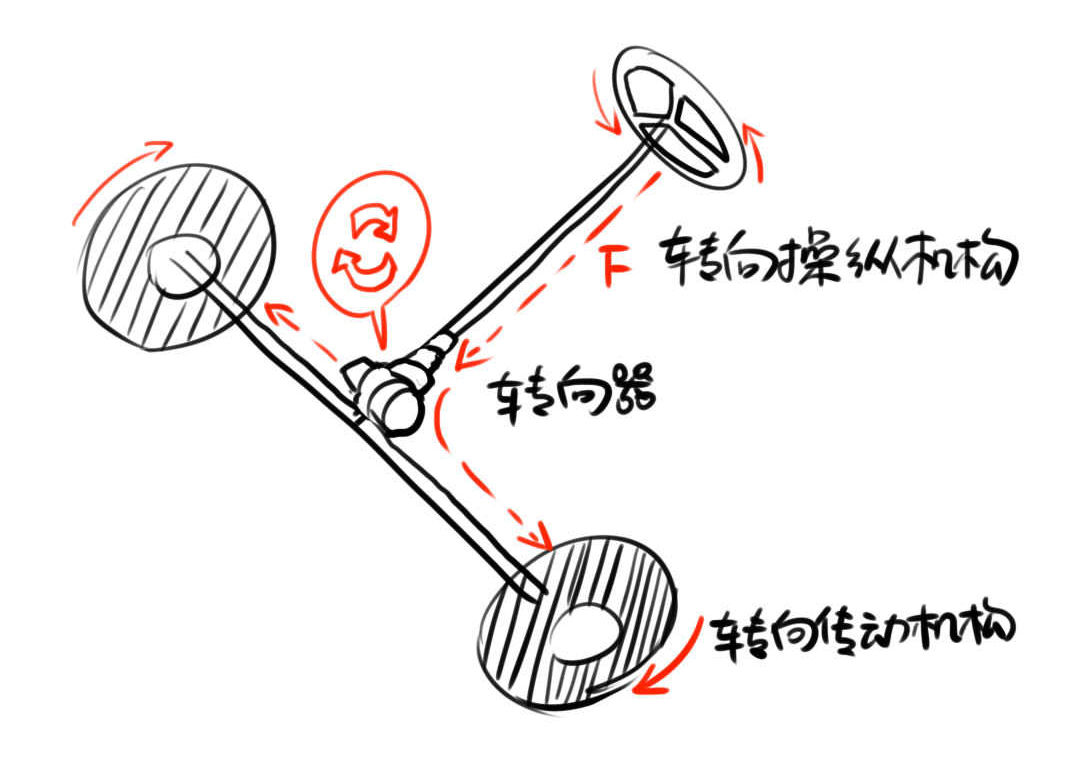

The steering system can be roughly divided into three parts: the steering control mechanism, the steering gear, and the steering transmission mechanism.

Steering Control Mechanism (the part we directly interact with when driving the vehicle): Just now, my master transmitted his physical strength through the steering wheel into me. I need to channel it and deliver it to the steering gear.

Steering Gear: Hmm… I feel a strong force flowing within me. It seems I need to quickly analyze, increase the effort, change direction, and transfer it to the tires.

Steering Transmission Mechanism: This time, the task received by the steering gear is to turn left by 45°. Hurry up and let the tire junior handle it.

Tires: Copy.

Emmm… It seems that the steering gear plays a crucial role in the power steering system, truly taking the center stage!

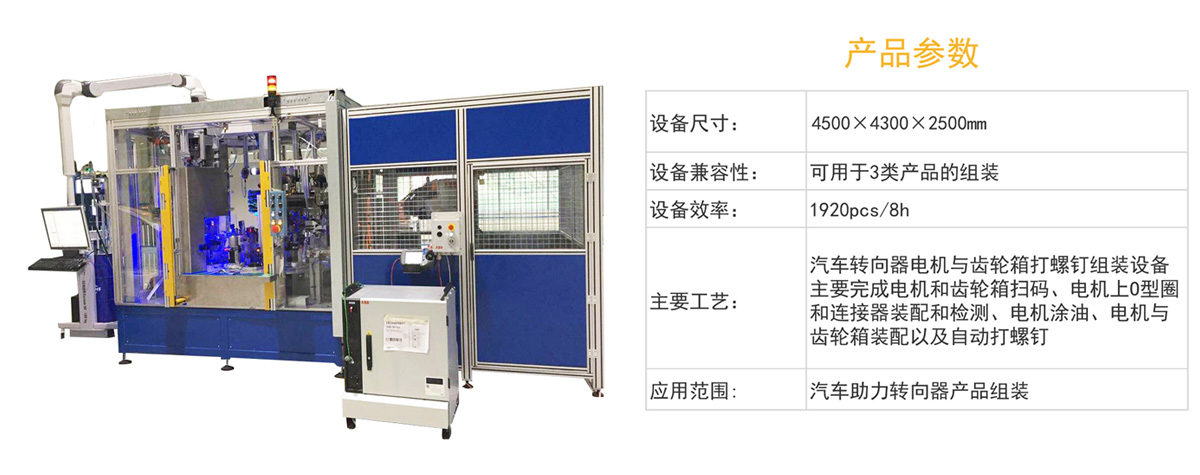

And the worm steering motor & gearbox assembly equipment provided by Bozhon perfectly meets the assembly needs of the steering gear motor and gearbox.

Key Process 1

A CCD camera checks whether the timing belt and O-ring are properly installed.

Key Process 2

The gearbox is filled with oil from all angles, with an accuracy of up to 3%.

Key Process 3

The screw assembly tightening system uses a servo motor to move the product to the screw assembly position. The electric servo offers ultra-high torque precision, with a standard deviation of less than 2%, enabling self-check, flexible expansion, and compatibility with various products.

Integrated Application

The Doubly Blessed control system isolates the equipment control layer from the process parameter configuration system, ensuring the safety and reliability of process parameters. Communication between PCs is established through ADS.

The assembly process takes only 15 seconds, making the assembly efficiency six times that of manual labor.

Flexible production meets the needs for multiple varieties and small batches: A single machine can accommodate the assembly of three different products, and more products can be added later according to the process.

High safety: Eight workstations are separated by partitions to prevent operators from being pinched while the equipment is operating.

The Bozhon Automotive Business Center website is officially online today!! Don’t miss out on checking it out!!

Login Method 1:

Visit the Bozhon official website: https://www.bozhontech.com/

Click on the homepage image below to enter.