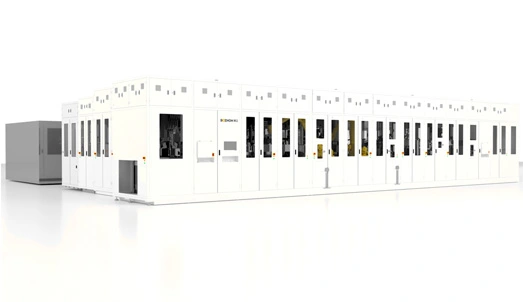

The New Energy Lithium-ion Battery Manufacturing Equipment suite features cutting-edge technology for battery production. It includes precise Cutting & Stacking Machines for electrode preparation, with Z-fold and Hotpress Lamination options enhancing battery layering efficiency. Specialized Electrolyte Filling Machines accommodate various battery types, ensuring optimal injection for Blade, Cylindrical, Prismatic, and Pouch batteries. Assembly lines for Pouch and Prismatic Battery Modules & Packs boost productivity in final assembly. This comprehensive lineup is engineered for mass production, advancing the future of energy storage.

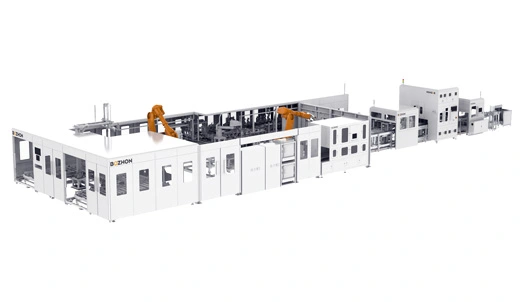

Dry electrode processing is poised to revolutionize lithium-ion battery manufacturing by offering a more sustainable and efficient alternative to the conventional wet slurry method. This innovative technique eliminates the need for solvents in the electrode coating process, thereby reducing the environmental impact and lowering production costs. By bypassing the drying stage required in wet processing, dry electrode processing significantly shortens the production time and reduces energy consumption, making the manufacturing process more efficient.

Furthermore, dry processing has the potential to improve battery performance. It can lead to increased energy density, as it allows for the creation of thicker electrode layers without compromising the integrity of the material. This advancement is crucial for the development of next-generation lithium-ion batteries that are required for longer-range electric vehicles and more powerful energy storage solutions.

As the demand for lithium-ion batteries continues to grow, driven by the surge in electric vehicle production and renewable energy storage systems, the adoption of dry electrode processing could be a game-changer. It offers a pathway to scaling up battery production sustainably, making it a key technology in the future of lithium-ion battery manufacturing.

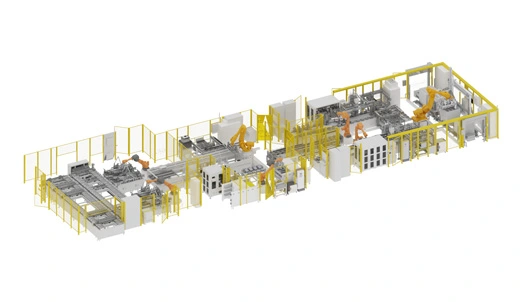

The evolution of battery formation techniques has been pivotal in enhancing the performance and longevity of lithium-ion cells, a cornerstone of modern energy storage solutions. Initially, formation processes were lengthy and energy-intensive, primarily focusing on activating the cell and solid electrolyte interphase (SEI) formation with basic charge-discharge cycles. However, as the demand for higher performance and faster production rates grew, so did the innovation in formation techniques.

Recent advancements have introduced more sophisticated formation protocols that optimize the initial cycling conditions, such as temperature, current rate, and voltage limits, to improve the electrochemical properties of the cells. These optimized conditions help in forming a more stable and uniform SEI layer, crucial for enhancing the cell’s cycle life and safety. Additionally, the integration of real-time monitoring and data analytics has allowed for the dynamic adjustment of formation parameters, tailoring the process to individual cell characteristics and thereby reducing variability in cell performance.

Moreover, the shift towards more energy-efficient and faster formation methods is reducing production costs and time, making lithium-ion batteries more accessible for a wide range of applications. This evolution in formation techniques is not just enhancing cell performance but also playing a significant role in the scalability and sustainability of lithium-ion battery manufacturing.