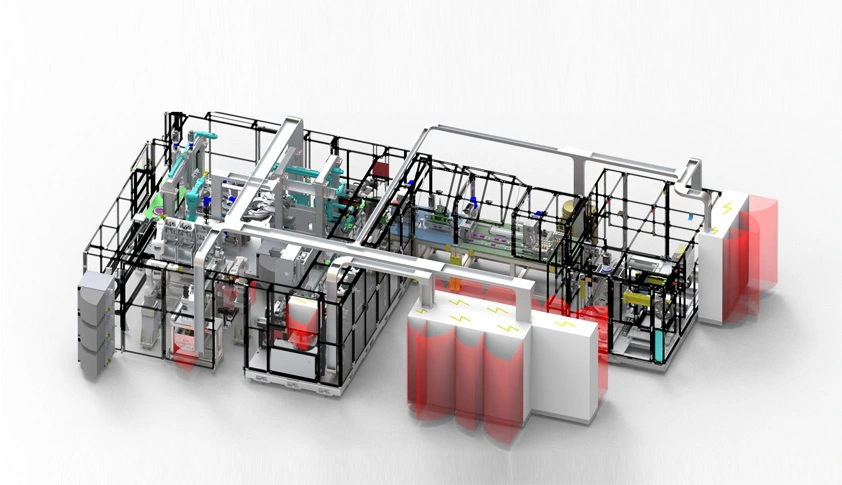

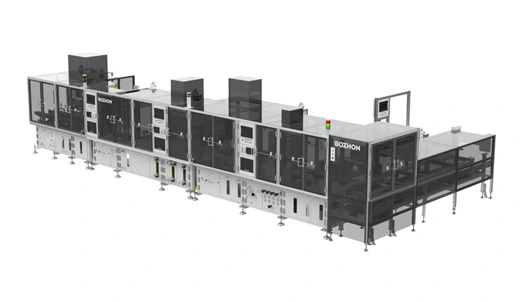

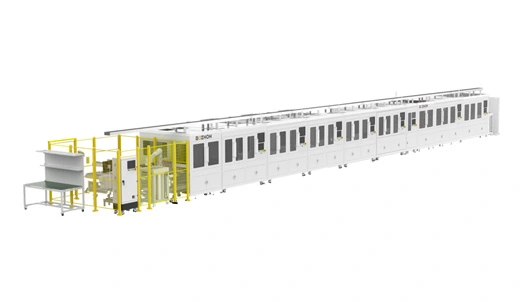

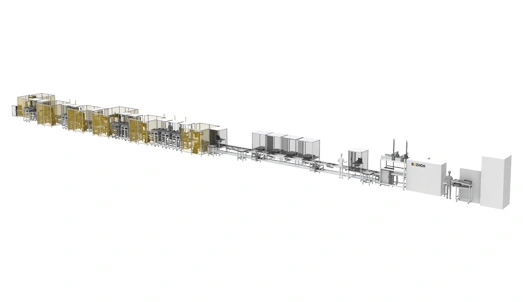

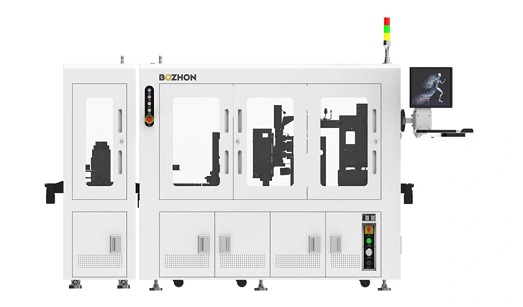

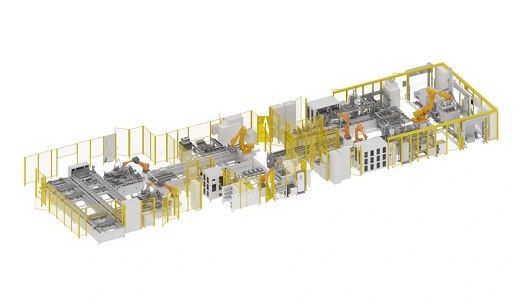

Provide One-Stop Industrial Equipment Solutions

E-mail:

bozhon@bozhon.com

Tel:

+(86)-0512-63414949

Add:

No.666, Huxin Road, Wujiang District, Suzhou, Jiangsu, China